In the car care market, it is currently fashionable to protect the exterior of the vehicle and decorate it at the same time. From the above products, today there is the mirror finish PPF that gives superior protectiveness to a vehicle while maintaining its appearance. That is why, deciphering the science of these advanced films and appreciating their market value is critical for B2B organizations. This article looks at why clarity is important in PPF and the powers that make a mirror finish feasible.

The Importance of Optical Clarity

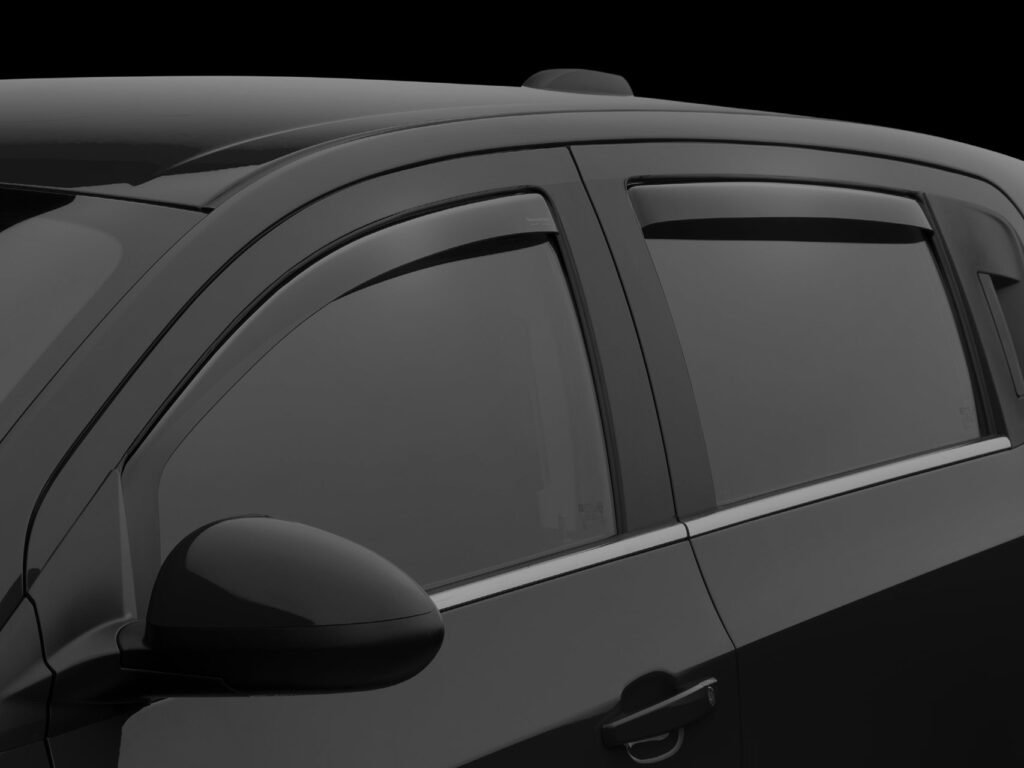

One of the most sought-after qualities of the paint protection films is that of clarity. Advanced PPFs exist in a form that makes them hardly noticeable after the application; this enables the paint of the vehicle to remain evident while offering protection. This clarity is not only the aesthetic one, it is the functional one as well: to safeguard the value of the vehicle and to keep the film from becoming the peel-off covering for the vehicle’s body.

If the B2B trade concerns ppf wholesale, another plus can be having films with better optical properties than those of competitors. Consumers, especially the ones who own luxury cars, value PPFs that offer the car a sleek and unique physical appearance that does not change the car’s physical appearance drastically. How this degree of resolution is attained is a matter for scientific engineering and the design and selection of high quality components from which there is little or no distortion or reflection.

The Technology Behind Mirror-Finish PPF

Getting a mirror like texture in the paint protection film brings a whole new level of technology that is employed to enable the film to not only protect but also give the car that glitters any look. The core of this technology is in the layered structure of the film with a top coat that has a high-gloss appearance that looks like a newly polished car.

The outer layer that forms the external part of the cover can be made out of thermoplastic polyurethane abbreviated as TPU is used because of its hardness and pliability. TPU can be applied to the form of the film to match it to the shape of the vehicle and that guarantees the best contact. Thirdly, TPU is self-healing, which means that it gradually fills in minor scratches and swirl marks and therefore contributes to the mirror finish of the vehicle.

For companies that strive to offer their clients the best in terms of product quality, it is necessary to find reliable manufacturers that offer non-bakes with additional functions such as self-healing and the creation of a true mirror surface. This guarantees the client not only security but also a product that will give their vehicles a better and enhanced appearance.

The Role of UV Resistance

The primary aspects of high quality paint protection films are one of which is resistance to UV radiation. Ultraviolet light can cause the pigments used in the paint to wear off thus reducing the looks of the car and therefore its resale value. There is mirror-finish PPF that guards against UV rays preventing the paint from fading away with its rich color.

These films also possess UV resistance that is incorporated by coating the films during the production process. These coatings can not only safeguard the paint but they also guard the film from becoming prone to yellowing, which is important in the preservation of the RCF mirror like sheen of the PPF.

The UV resistance of the PPFs is crucial for the B2B enterprise, especially in areas where the intensity of the sunlight is high. As such, through offering products that will meet protection and clarity needs, firms are able to satisfy those clients who are interested in long lasting glossy protection.

Combining PPF with Ceramic Coatings

Although the mirror finished PPFs give maximum scratch protection and luxury looks, they can be paired with ceramic coatings to polish the exterior and durability of a car. Ceramic coatings give an extra layer of protection from the environmental particle deposition, water spots and other chemical formations and at the same time, improving the gloss of the PPF.

The best ceramic window tint also has to serve this need because the products can also enhance the interior section protection by offering UV shield and heat control. This approach makes it possible to offer a high level of security inside the vehicle as well as outside ensuring that the vehicle is very much secure hence considered by the high end clients.

To all the B2B companies, it is also advisable to invest in the mirror-finish PPF and Ceramic Coating package that offers your customers the best. Thus, together with providing the increased level of protection, this variant is more visually appealing and therefore, may become attractive for the clients.

Meeting Market Demand

This means that as the market for high-quality products continues to grow businesses need to consider meeting the needs of their clients through products that are updated to suit the market. This growth in the usage of the mirror-finish PPF is seen in the light of an overall trend of coatings that are not only functional in terms of protection, but also in terms of appearance enhancement.

Thus, for the B2B companies operating in the ppf wholesale, competition forces them to stock a variety of products to suit the customer’s taste. This encompasses not only the polished PPFs, but also coatings such as ceramics and windows tinting in high performance. Having a range of products, companies ensure that they would be able to capture more customer attention and fulfill the needs of many consumers.

One of the manifestations of the progress in the technology of car care is the presence of protective metalized paint coatings. Due to their high light transmission, durability, UV protection and the ability to heal themselves, these films provide the best shield while at the same providing the car a sleek look. Hence for B2B business and organizational buyers to be relevant in those markets they require to embrace those novelties produced by concentration on the technology that enhances clarity. This way businesses can satisfy the increasing need for impressive PPF products as well as added services such as ceramic coatings.